For many centuries, dams have played an essential role to store water for different purposes, such as irrigation, water supply, hydroelectric power and flood control. Today agricultural irrigation and hydroelectric power, also known as hydropower generation, are by far the most common functions for dams. Sika supplies innovative solutions for the largest and technically complex dam and hydropower plant designs.

Today, there are about

60,000

Approximately

300

every year.

planned across the world’s

major cities by 2035, and

80 years

more journeys will be

possible as a result.¹

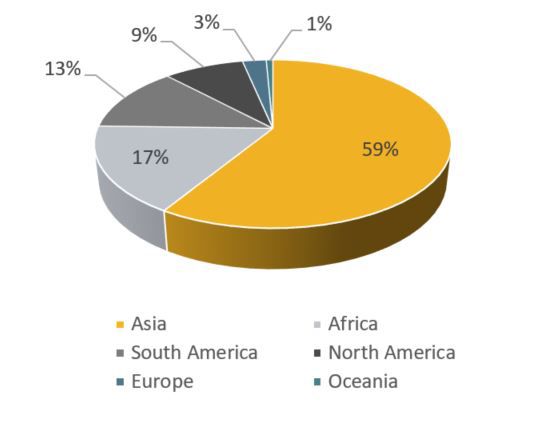

Planned Hydro Capacity by Region²

Hydropower generates

16.4%

2050,

will double.⁴

Systems Plus Knowhow

Dams are structures that present particular challenges and complexities. Sika’s specialists understand these and provide advice with problem solving solutions to safely and securely meet all necessary design, construction and in-service performance requirements, for both new build and renovation projects. Sika solutions make a positive contribution to the overall performance of all types of hydraulic structures, while also potentially reducing construction and operating costs.

Sika is your single source of integrated, fully compatible solutions for dams and hydropower plants throughout their life cycle in the following areas:

Admixtures for concrete and shotcrete

Waterproofing

Concrete protection and repair

Sealing, bonding and steel protection

Flooring

Roofing

Technical support and onsite services

Systems Plus Knowhow

1. Main Dam

Dams can be exposed to a wide range of stresses and strains, starting internally with the thermal stress resulting from mass concrete construction, the high static and dynamic loadings, the hydrostatic water pressure in construction and in service, plus additional seismic forces in many regions. The construction materials have an essential role in being able to resist all of these forces. Conventional concrete dams are obviously stronger and more stable than earth dams, but at the same time they are also much more expensive. Roller-compacted concrete (RCC) technology uses concrete with “no-slump consistency” that usually provides the most cost effective construction material for dam building.

Requirements for Successful Dam Construction

- Highly durable concrete with reduced permeability and excellent performance

classifications - Extended workability and increased setting time in order to complete the placing procedures (essential for RCC)

- Correctly engineered and practical sealing solutions for each and every type of joint in the structure

- Highly durable grouting products

- Steel protection solutions to reduce corrosion in CVC structures

2. Slope Stabilization

One of the many applications of shotcrete is slope support. Slopes are generally designed so that the rock mass can support itself, but frequently this requires additional support. Shotcrete is also ideal for slope stabilization due to its ease of adaptation to site profiles and requirements, its capacity to stick to the rock and its high early strength and resistance. As shotcrete is spray-applied, the material is compacted against the surface to also fill any cracks and prevent any loose materials from falling. Shotcrete therefore provides a protective coating over the slope’s surface and also helps to consolidate and stabilize or ‘anchor’ the surface. In addition, drainage systems such as Sika FlexoDrain can be fixed into and onto the slope with shotcrete, which is important for ensuring future stability.

3. Spillway and Intake Structures

In a hydropower plant, the intake structures and the spillways are some of the associated secondary structures that are required along with the main dam itself. These structures are usually reinforced concrete structures which are used to collect water from the reservoir. The type of intake structure generally depends on its location and function as well as the other associated hydraulic structures that make up the plant, such as the concrete towers and artificial banks.

4. Underground Work

Tunnels are usually required in dam building projects where the topographical conditions prevent simple open-channel construction. For example, water diversion tunnels are commonly required additional structures for large dam projects. When a dam is to be built, a tunnel is frequently bored first, in order to divert water away from the actual dam construction site itself and so that it essentially bypasses it.

The Sika product range for tunnels and below ground construction is absolutely extensive and the fruits of more than 100 years of specific experience, continuous improvement and innovation in tunneling. This huge product range comprises all the latest technologies to provide the best and most cost effective solutions for your projects.

5. Powerhouse

The main powerhouse hosts the turbines, generators and their necessary auxiliary equipment and the size of the structure obviously depends on the dam design and the types, dimensions, and number of generating units installed. The building is usually a large reinforced concrete structure having three distinct areas: the main powerhouse or generator room, the erection bay for transformer tanking and un-tanking, plus the service area, which generally includes the main control room, offices and other areas for auxiliary equipment.

6. Penstock and Gates

The dam penstocks are large pipes that control and convey pressurized water to the powerhouse turbines. These can be designed and positioned to run along at ground level, or below ground as a buried pipe, principally depending on the topography and geology of the site. There are two different layouts that are commonly designed and used, which are to have a separate penstock for each generating unit, or a larger penstock with branches into each of the generating units from close to the powerhouse. Penstocks themselves are usually made of steel, but plastic and concrete sections can also be used. Powerful gates and mechanical filters are essential to avoid any solid materials that may be picked-up, from entering and damaging the electromechanical generation equipment of the turbines.

7. Dam Repair

Ensuring dam safety allows to protect the people’s lives and property and to foster the development of the society. However, existing dams can be vulnerable to severe hazards such as floods and earthquakes, and even small defects in dams can lead to significant damages due to service and environmental conditions. Concrete cracking is the deficiency most often reported. Other major problem areas are seepage, spalling and abrasion especially on spillways.

Since many of the existing dams today are operating beyond their normal 50-year service life and will have to continue to be operable, there is a great need for solutions concerning the repair and rehabilitation of these structures.